BENEFITS OF USING XOREX STEEL FIBER

CRACK CONTROL: The primary function.

The fibers bridge across micro-cracks as they form, holding the concrete

together and controlling crack width. This improves durability by reducing

water and chemical ingress.

IMPROVED TOUGHNESS & IMPACT

RESISTANCE: Steel fiber reinforced concrete (SFRC) can absorb

significantly more energy than plain concrete. It is more resistant to impact,

blast, fatigue, and abrasion.

FASTER CONSTRUCTION: No more

time-consuming tasks of cutting, bending, and placing rebar or mesh. The fibers

are simply added to the concrete truck at the batching plant or site.

REDUCED LABOR

COSTS: The labor savings from eliminating rebar

installation are substantial.

BETTER DURABILITY: By controlling

crack width, it protects the concrete from corrosion-causing agents, thereby

enhancing the long-term service life of the structure.

DESIGN FLEXIBILITY: Enables the construction of complex shapes and thin-shell structures that are difficult to reinforce with rebar.

COMMON APPLICATIONS

INDUSTRIAL FLOORS: The most common

application. Ideal for warehouses, distribution centers, and heavy-duty

industrial floors where high impact and abrasion resistance are needed. They

allow for the elimination of saw-cut joints or wider joint spacing.

SHOTCRETE: Used for tunnel linings,

slope stabilization, mining, and swimming pools. The fibers prevent rebound and

create a more ductile, crack-resistant layer.

PRECAST ELEMENTS: Used in precast

panels, pipes, manholes, and vaults to improve handling strength, reduce

cracking, and sometimes replace secondary rebar.

PARKING LOTS AND PAVEMENTS: Provides

enhanced performance for heavy vehicle traffic.

BLAST-RESISTANT STRUCTURES: Its high energy absorption capacity makes it suitable for structures requiring enhanced security.

SPECIFICATIONS

LENGTHS: 25mm, 30mm, 35mm, 38mm,

40mm,50mm.

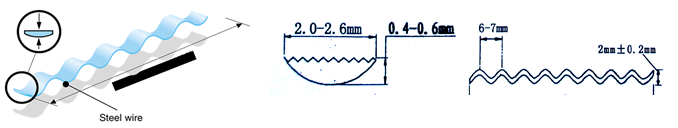

WIDTH: 2.0-2.6mm,

THICKNESS: 0.4-0.6mm,wave length

is 6-7mm,wave height is 2mm±0.2.

CHEMICAL INDEX:

|

Mn |

Si |

S |

P |

|

|

0.07-0.12 |

0.8-1.25 |

0.07MAX |

0.03MAX |

0.03MAX |

TENSILE STRENGTH:>800Mpa