DETAILED BREAKDOWN

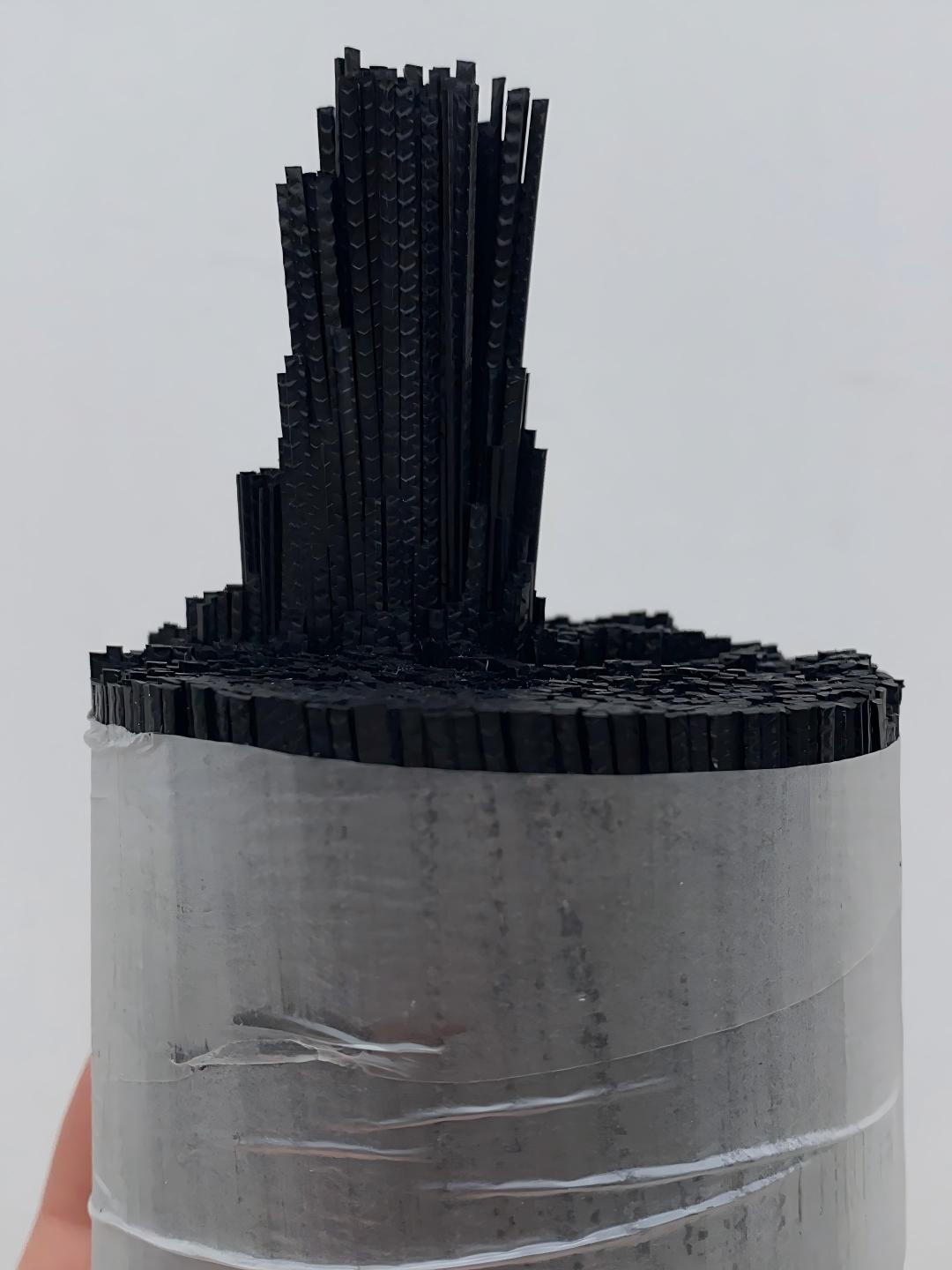

FOR MACRO PP FIBER:

1. MACRO

This refers to the size and

scale of the fiber.

Macro-fibers are large, typically over

0.3 mm in diameter and several inches long. They are visible to the naked eye

and provide "bridging" capacity across cracks that have already

formed.

This contrasts with Micro-fibers,

which are very fine, hair-like fibers used primarily to reduce plastic

shrinkage cracking in the first few hours after concrete is poured.

2. PP (Polypropylene)

This is the base material the

fiber is made from. Polypropylene is a popular plastic polymer chosen for its

key properties:

Chemically Inert: It does not react

with water, alkalis, or acids, making it highly durable in the harsh

environment of concrete.

Corrosion Resistant: Unlike steel, it

will never rust.

High Melting Point: It can withstand

the heat generated during concrete curing.

Low Cost: It is an economical choice

for large-scale construction projects.

3. FIBER

In this context, it's a synthetic,

discontinuous reinforcement. This means:

Synthetic: Man-made from plastic.

Discontinuous: It comes in individual

pieces (like billions of tiny hairs) mixed randomly throughout the concrete, as

opposed to a continuous mesh or rebar grid.

Reinforcement: Its primary job is to

improve the concrete's mechanical properties.

PRIMARY

FUNCTION:

The main purpose of Macro PP Fiber is

to replace or supplement traditional steel mesh (welded wire fabric) as

secondary reinforcement in concrete slabs-on-ground (like industrial

floors, pavements, and warehouses).

It provides three key

benefits:

Crack Control: This is its primary

job. When micro-cracks in concrete begin to widen, the macro-fibers bridge

across the crack, holding the concrete together and transferring stress. This

prevents the cracks from becoming large and problematic.

Toughness &

Impact Resistance: Fibers increase the energy

absorption capacity of concrete. The concrete becomes more resistant to

shattering, abrasion, and impact from heavy loads or dropped objects.

Spalling Resistance: In concrete surfaces, fibers help hold the material together,

reducing the risk of chips and fragments breaking off the surface.

SPECIFICATION:

|

SrNo |

Test Item |

Unit |

Index |

|

1 |

Length |

mm |

48/55/65 |

|

2 |

Filament Diameter |

mm |

Width:1.37+/-0.1mm |

|

3 |

Density |

g/cm3 |

0.91 |

|

4 |

Tensile Strength |

Mpa |

650 |

|

5 |

Acid/Alkali resistance |

- |

Yes |

|

6 |

Elongation |

% |

15 |

|

7 |

Melting point |

°C |

170 |

|

8 |

Modulus of elasticity |

MPa |

10000 |

PACKING: 5kg/box, 1200-1300kg/pallet, 12000kg/20’ container,

24000kg/40’ container